Published August 2024

Brandon Fainstad, MD1

1 Associate Professor, Division of General Internal Medicine, University of Colorado

General Instructions

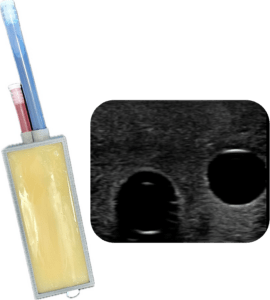

Each task training model utilizes heat-resistant 3D printing material to construct the external shell and the internal anatomy that ultrasound cannot penetrate (e.g. ribs and spine).

3D printing materials: We recommend using glass filled nylon or heat resistant resin. More common filaments such as PLA and ABS will melt and deform when pouring in the molten balistics gel.

Ultrasoundale tissue: We use three components: clear ballistics gel, skin tone pigment, and polyethylene glycol (adds echogenicity). These components are melted and mixed at 250 degrees F for 4 hours in a common kitchen slow cooker then poured into the 3D printed shell.

3D printing file

How to construct

How to use

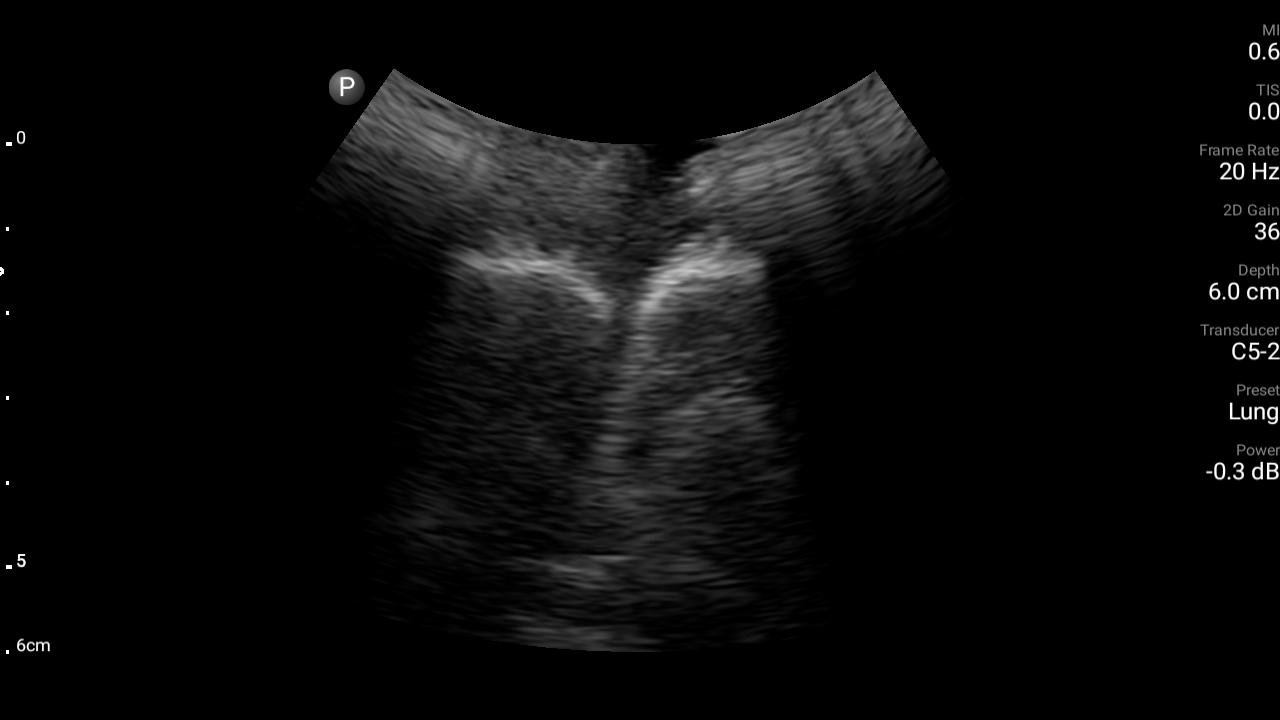

A-line Task Trainer

How to use the model